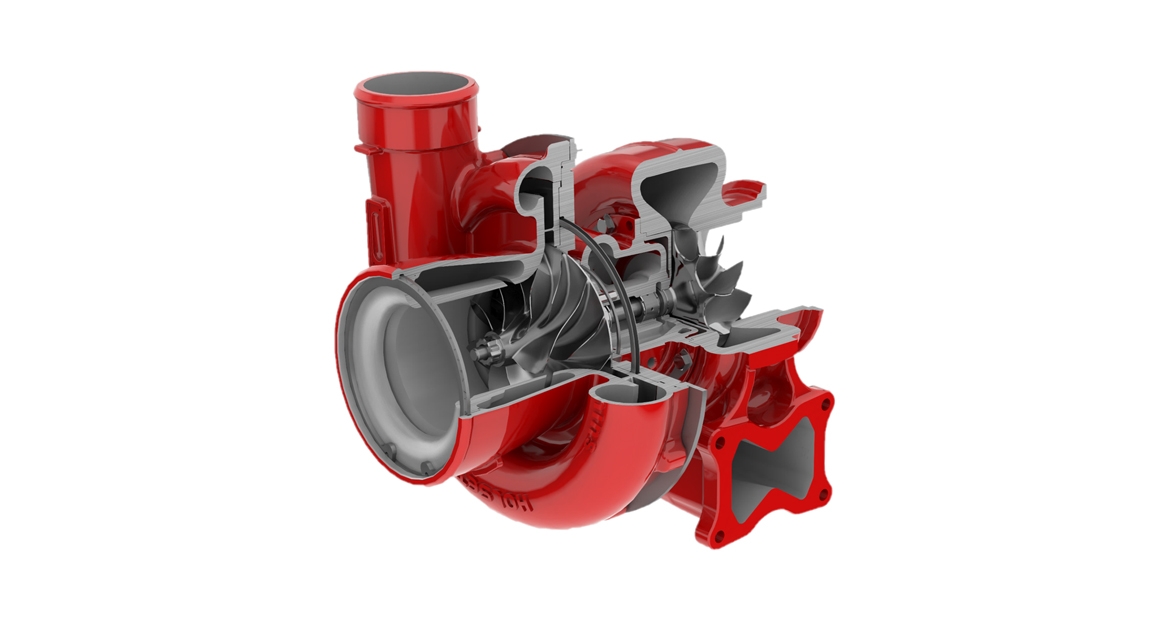

The Holset VGT turbo (Variable Geometry Turbocharger) is a most advanced component designed to optimize engine performance in all kinds of operating conditions. It adjusts its internal geometry dynamically to provide superior efficiency, improve power delivery, and lower emissions. Now, this technology has become a key feature in modern diesel engines.

How Does a Holset VGT Turbo Work?

Basic Turbocharging Principles

A turbocharger compresses air before it enters the engine to increase the air density. This allows the engine to burn more fuel efficiently, resulting in greater power output. Traditional turbochargers rely on fixed geometry, which can lead to inefficiencies at varying engine speeds.

Variable Geometry Working Principle

The Holset VGT turbo improves traditional turbocharging by applying movable vanes inside the turbine housing. These vanes adjust their position to control the flow of exhaust gases to the turbine wheel. The mechanism allows the turbo to operate effectively at different engine speeds.

- At Low Engine Speed

At low RPMs, the vanes close partially to narrow the pathway for exhaust gases. Then the exhaust gas to the turbine flows faster to help the vanes spool up quickly. The result is reduced turbo lag and improved low-speed torque, which is essential for tasks such as towing or city driving. - At High Engine Speed

At higher RPMs, the vanes open wider to allow more exhaust gas to pass to the turbine. This prevents excessive pressure buildup and ensures optimal power output. The design balances airflow and maintains efficiency, even during demanding conditions.

The Role of Electronic Control Systems

Modern Holset VGT turbos are typically equipped with electronic actuators controlled by the engine’s ECU (Electronic Control Unit). These systems constantly monitor variables such as engine speed, load, and exhaust pressure to adjust the vane position in real-time. This precise control improves the performance, fuel efficiency, and emissions of the engines.

Other Assistive Technologies and Designs

Many Holset turbos incorporate additional features, such as advanced durable materials and noise-reduction mechanisms. The robust design of the Holset turbocharger ensures engine reliability under heavy-duty conditions, making it a preferred choice in commercial vehicles and performance applications.

Benefits of a Holset VGT Turbo

- Improved Power Delivery

The variable geometry design allows the turbo to deliver power smoothly across a wide RPM range, so as to enhance overall drivability. - Enhanced Fuel Efficiency

By optimizing air delivery at all speeds, the Holset turbocharger helps improve fuel consumption, reducing fuel costs. - Lower Emissions

Precise control of exhaust flow reduces harmful emissions, helping vehicles comply with strict environmental regulations. - Reduced Turbo Lag

Quick spooling at low RPMs ensures minimal lag. Then the engine becomes more responsive especially during acceleration. - Durability and Reliability

Built with high-quality materials, the Holset VGT turbo can withstand extreme temperatures and pressures, ensuring a long service life.

Final Thought

The Holset VGT turbo revolutionizes engine performance by dynamically adjusting its geometry to meet varying demands. With enhanced power, efficiency, reduced emissions, and other benefits, it’s a cornerstone of modern diesel technology. Its innovative design ensures reliability and adaptability for diverse driving needs and makes it stand out in the turbocharger market.